In our strategy of being a global supplier for manufacturers of heat exchangers, we can provide all the complementary machines necessary to produce the components to complete the heat exchange coils.

The complementary machines integrate the others to supply complete industrial plants.

For the production of finned exchangers C.M.S. designs and builds:

- machines for the production or completion of tube sections in the form of elbows or bends, as the crossover machine, the elbow bending and cutting machine, the return bending machine and the ring-assembler;

- machines used for the processing of headers or manifolds, such as the manifold drilling machine or the manifold closing machine.

Thanks to the flexibility of operation, each machine can be provided with dedicated equipment for each tube diameter, geometry, thickness and material.

When producing large quantities of heat exchangers having the same length, the brazing process of the bends can be automated through the use of automatic gas brazing machines. For particular uses, with the coil bending machines it is possible to bend the heat exchanger coils either continuously or by bends with predefined angle and radius.

The Return Bender (RB) is designed to make bends of 180° and straight tubes starting from coils of copper and its alloys and aluminum.

The Crossover (CRO) is a special return bender and it may be used for a wide range of tubes processing and it may be totally automatic or semiautomatic.

The nipple bending and cutting (LFM) has been designed for a fast execution of the straight tubes (cut portions) and bended tubes (elbows) between 0 and 110°, with a length included between 0.6in/15mm and 11.8in/300 mm.

The Ring machine (RA) is used to insert the rings of brazing material at the ends of the bends at 180° in order to use them for processes of automated brazing.

The Manifold drilling (MDM) is the perfect solution to drill manifolds in copper and its alloys, aluminum, steel, stainless steel, etc. with max. diameter of 220mm. It may have or not the tools warehouse and may operate both in drilling and milling mode. It is then in a position to perform drills out of the axis.

The tube end closer (SM) performs the closing of the manifolds ends in copper, with max. external diameter of 108 mm, by plastic deformation. To this purpose, it uses special tools placed as a revolution at the ends of the manifold itself, which deform it progressively and permanently.

The horizontal axis coil benders (CB) have been designed to bend finned coils with single or multiple bends in manual, semi-automatic or automatic cycle.

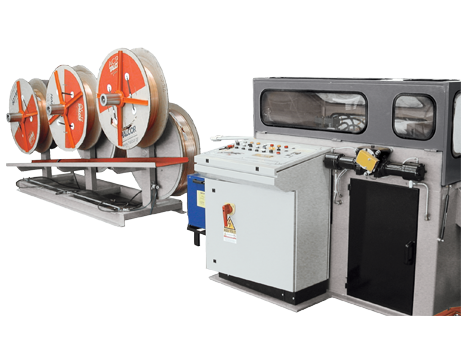

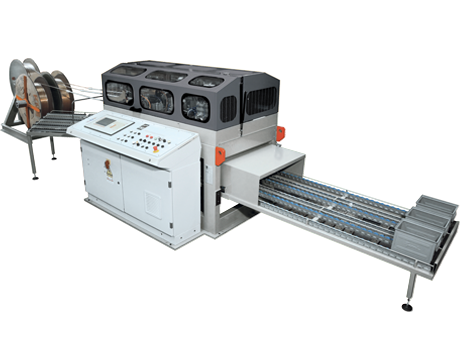

CMS designs and manufactures Brazing Machines (BR) dedicated to automatic brazing of the return-bends of coils with max. height of 5.25ft/1600 mm. They are composed by...

To obtain an estimate or consultancy on the various machines for the production of heat exchangers, please contact the company.

REQUEST INFORMATION